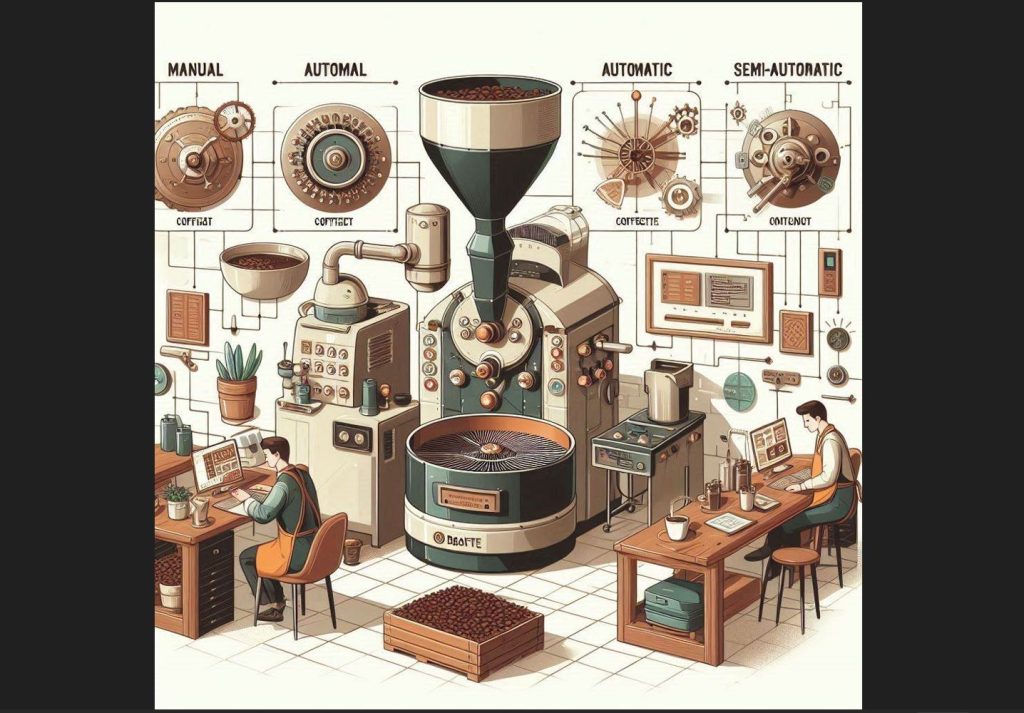

Most machine manufacturers market their products with definitions such as manual, semi-automatic, automatic, and fully automatic machines. So, what should the content of these definitions be? When referring to an automatic or semi-automatic machine, what should the automation system include? This topic can appear somewhat vague from the perspective of machine customers and may sometimes result in erroneous purchases. Although making a sharp distinction is difficult, classification can be done based on distinct features.

According to us, the ideal definitions and machine features under optimal conditions should be as follows:

Manual Machine:

- Machine functions and equipment are controlled by the operator.

- During preheating, the temperature value can be automatically controlled based on the target temperature via a controller.

- Drum/fan speed settings and flame signals during the coffee roasting process are manually adjusted by the operator during roasting.

- Discharging the coffee from the drum and operating the cooling systems are at the operator’s discretion.

- Profile repetition is not available in this type of machine. Each new profile is under operator control, so consistency may be low.

- Optional equipment (loader, destoner, afterburner) controls are operated by the operator as needed.

Semi-Automatic Machine:

- In this type of machine, the preheating temperature is automatically managed by a temperature controller or PLC.

- Loading green coffee, discharging, and cooling processes are performed by the operator.

- Lids are manually opened and closed by the operator; there are no pistons on the lids.

- There should be interfaces where the operator can pre-enter or define the information related to the desired profile.

- Actions during the roasting process (drum/fan speeds, flame signals) are automatically managed via a PLC or controller.

- Post-roasting mixing and cooling processes are under operator control. Cooling and mixing durations can be added to such systems.

- Pistons used for product discharge and loading are not present in these machines.

- Optional equipment (loader, destoner, afterburner) controls are operated by the operator as needed. Specific durations and operating conditions for each piece of equipment can be added.

Automatic Machine:

- In an automatic machine, preheating is automatically performed according to the target temperature value.

- There should be an interface for preparing or creating profiles (recipes).

- During profile-repeated roasts, drum, fan, or flame signals are automatically managed by a PLC or controller based on previously saved profile values.

- Processes such as discharging green coffee into the drum, unloading roasted coffee from the drum, and discharging cooled coffee from the mixer are automatically performed using pneumatic pistons or motors. Durations and conditions may vary depending on the machine manufacturer or user.

- The durations and methods of processes like cooling and mixing are automatically defined and executed.

- Optional equipment (loader, destoner, afterburner) can be automatically integrated into the roasting process as desired.